How Will We Handle Lunar Dust Without Landing Pads?

NASA’s return of humans to the Moon in 2024 will involve large numbers of Moon landings with equipment and supplies. New technology must be used to mitigate the lunar dust ejected at high velocities when landing large Moon landers on the lunar surface. When a high-velocity engine plume nears the surface of the Moon it can create a crater beneath the lander and accelerate loose Moon regolith to ‘sand blast’ near and distant landed and orbital assets. The Apollo lunar modules were about ten metric tons (mT) and saw this effect, but didn’t have to worry as much about damaging structures on the Moon or spacecraft in orbit as there were few. Since many more structures, spacecraft, and potentially long term habitats could happen this time, a solution is needed. Looking forward, some effects will be seen even with the one to five mT Commercial Lunar Payload Service (CLPS) missions, and they will be numerous. But much harder to contend with are the larger Human Landing Systems (HLS) planned with landing masses of about 20 mT to potentially hundreds of mT. Luckily there are many potential solutions being pursued that will address these issues. Some of these include alterations to lander design, in-situ creation of landing pads with local materials, and a newly proposed technology that would see landers create their own landing pads during the landing process.

Source: Matthew Kuhns, Masten Space Systems Inc.

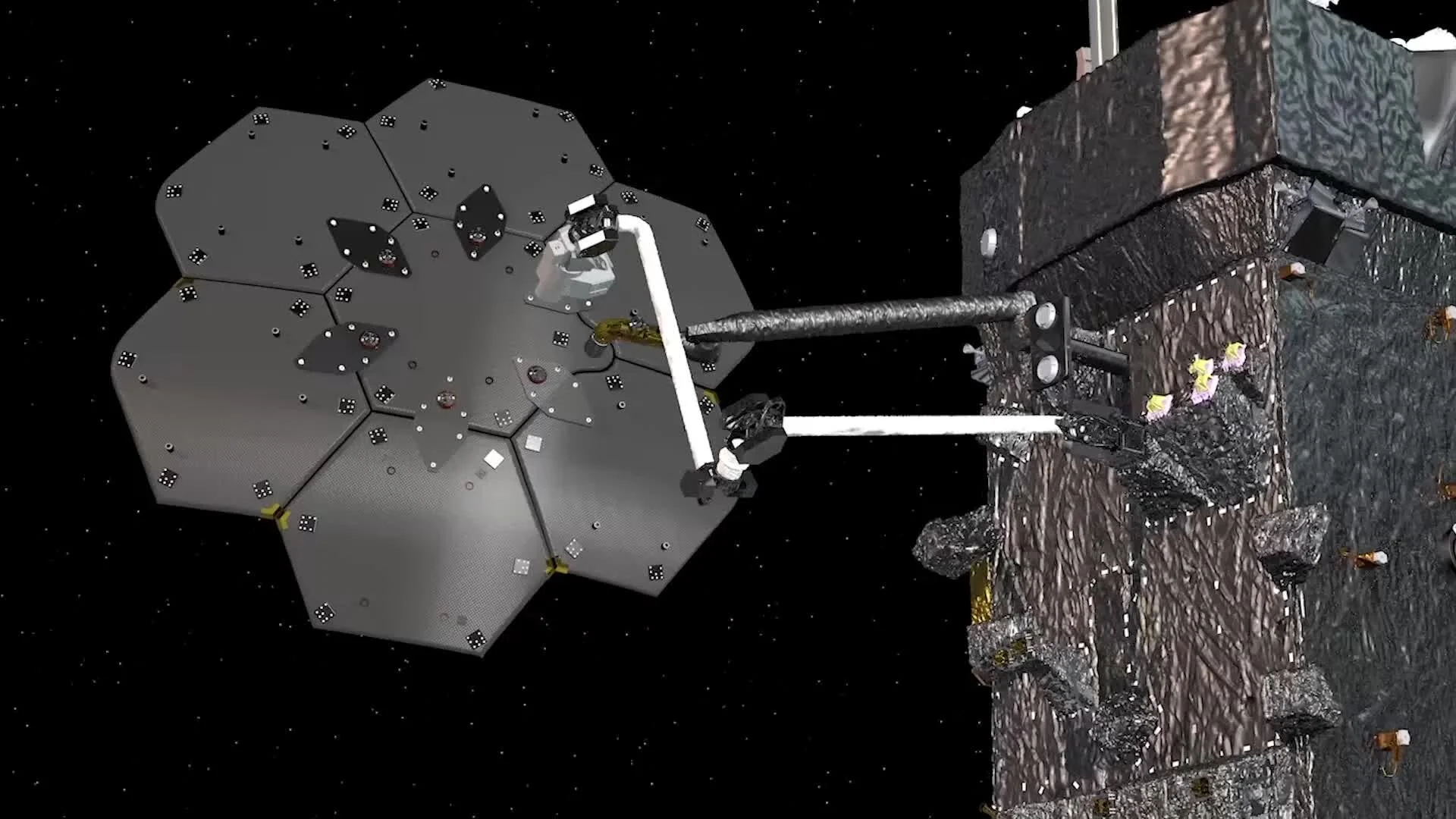

NASA’s recent selection of Masten Space Systems for a NASA Innovative Advanced Concepts (NIAC) Phase I will fund their development of the instant landing pads concept. This method involves the Masten in-Flight Alumina Spray Technique (FAST) where particles are injected into the rocket plume during landing so that the plume melts and then ballistically deposits them on the surface below, forming a landing pad. If Masten can demonstrate the effectiveness of this method, it will provide an option that is less logistically complex and likely less expensive than most proposed landing pad production schemes. This is because it doesn’t require a special mission dedicated to landing on the Moon with equipment needed to build a landing pad using in-situ resources, saving time and millions of dollars.

Diagram of how the Masten Space Systems FAST method will create a landing surface via particles injected into the thruster exhaust. Source: Matthew Kuhns, Masten Space Systems Inc.

NASA’s recent selection of a lunar variant of the SpaceX Starship as one of three awardees to design and build human landing systems revealed a new solution being pursued by SpaceX to mitigate engine plume effects during lunar landing. During the terminal descent, for the last few tens of meters before reaching the surface, Starship uses high thrust methane/oxygen RCS thrusters located high up on the vehicle to land. This is done instead of firing the large raptor engines beneath the vehicle in close proximity to the lunar surface. The RCS thrusters are located high up on the 160ft (50m) tall vehicle to distance their thrust from the surface as well. By going this route instead of relying on the huge Raptor engines for the final landing burn, the spacecraft can protect the landing surface from the concentrated brunt of its landing thrust.

In a recent discussion on the Deep Astronomy YouTube channel, Nick Cummings of SpaceX stated that the new methane/oxygen RCS thrusters share a lot of heritage with the Raptor engine, and that testing activities are planned to start next year.

SpaceX Human Lunar Lander Starship. Source: SpaceX.

The high-mounted RCS thruster method of landing will significantly reduce landing plume acceleration of regolith and creation of a crater beneath the vehicle, which is an especially significant problem for very large Moon landers. While details of this landing architecture are still sparse, more will be known soon. SpaceX will be further refining the lander design, development, and maturation plans until February 2021 as part of the NASA HLS firm-fixed, milestone-based contract.

Once landed on the Moon, many methods are under study to produce a landing pad for other vehicles to use. While all methods rely on first landing your equipment to build a landing pad on the unprepared lunar surface, there are added benefits to this method. While methods are in development to create a type of landing pad during landing or to reduce the effects of landing thrust, they cannot perform as well as pre-prepared landing areas. By building a landing pad on the surface, care can be taken to build it in a much more resilient manner for multiple landings. Landing pad construction equipment can also build a type of berm around the landing pad to help stop debris and the accelerated plume that would otherwise flow away from the landing vehicle and across the lunar surface picking up more regolith. There are various plans being studied for landing pad construction, including the use of a microwave source to sinter lunar regolith into a solid and the use of a prepared binder to form a type of lunar regolith basalt concrete.

The return to the Moon will require us to tackle many challenges that even Apollo didn’t have to directly resolve. As with all engineering problems there is not one single solution, so in this case many approaches are being taken to contend with the many problems posed by landing on the Moon’s dusty surface. While some interim solutions may somewhat alleviate the problem using new solutions during landing, the efficient long term solution will involve pad construction on the lunar surface. To produce that long term solution, the very same dusty regolith that poses the hazard will be utilized as a space resource in the manufacture of landing pad infrastructure. This is a great example of the benefit of space resource utilization, as not only are the resources of space useful for making propellant or supplying manufacturing, but they can be utilized to resolve the same hazards that they themselves pose.

References

https://www.nasa.gov/directorates/spacetech/niac/2020_Phase_I_Phase_II/Instant_Landing_Pads_for_Artemis_Lunar_Missions/

https://www.nasa.gov/press-release/nasa-names-companies-to-develop-human-landers-for-artemis-moon-missions

https://spectrum.ieee.org/tech-talk/aerospace/space-flight/nasa-landers-instant-landing-pads

https://twitter.com/SpaceX/status/1255907213568208896

Concepts for an In-Situ, Reusable Construction System for Lunar Landing and Launch Pads, Elizabeth Scott, Space Resources Roundtable 2019, Colorado School of Mines, CO. Link.

Construction with Regolith, Robert Mueller, Kennedy Space Center, FL. Link.